Marine generator drives

Tunnel Gear Boxes (GDG) - Fotos: Sebastian Kaps . Dessau

At Getriebetechnik Dessau and it's former company's named ABUS/ASUG the manufactoring of marine gear reducers has got a tradition of ore than 50 years. The delivery of high quality and precision under consideration of all specific client's requests are basis for each projekt. Until now, more than 7.000 marine reduction gearboxes have been built under different classification societies. The gear reducers are worldwide used to the contentment of the clients according to the type among other things as main drives of cargo and passenger ships and as auxiliary drives such as generator plants.

Arrangements

The generator gear boxes enables the shipboard production of electricity by means of the low speed main engine of the vessel. The gear units are of two-stage design to increase the propeller speed to the requested generator speed. The transmission ratios are between 1:5 and 1:18.

Tunnel Gearbox (GDG), Gearbox in standard design:

- Hollow shaft in plain bearings

- Secondary PTO

- Gearbox can be equipped with lamella clutch in case of request

- Hollow shaft connected with high elastic coupling where as the generator shaft is equipped with flexible coupling (both GTD supply)

Additional solutions:

- PTH (take home device) with propeller shaft clutch (PTC) switchable during standstill

- The PTC is equipped with thrust bearing

Front End Gearbox (STG)

- Flanged-on gearbox

- Seperately mounted gearbox

Front-End Gearbox (STG)

The programme of marine reduction gearboxes includes:

- Single Engine Reduction Gearboxes (GVE, GHE)

- Multi-Engine Reduction Gearboxes (GHD)

- Generator Gearboxes (Tunnel Gearboxes GDG, Front-End-Gearboxes STG)

- Marine Reversing Gearboxes (MS, SW, SWGK)

- Marine Auxiliary Drives

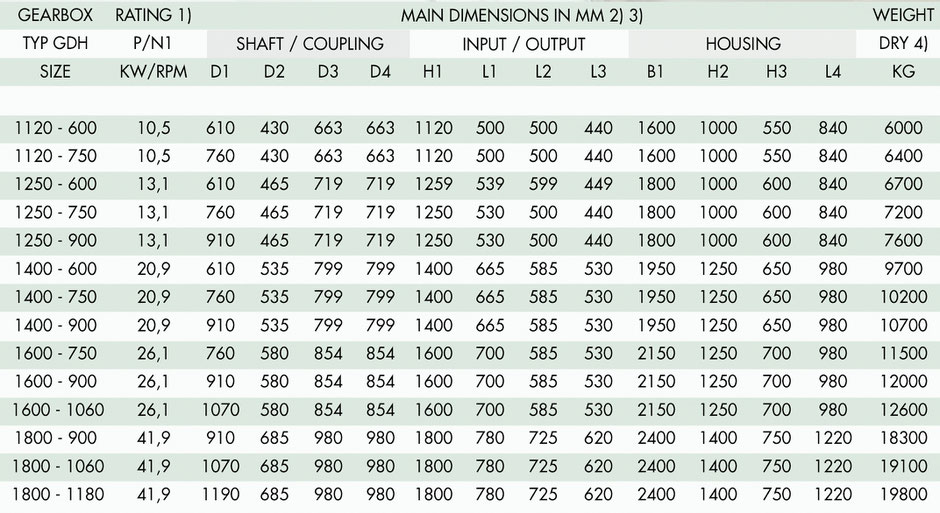

Main Dimensions of Hollow Shaft Gearboxes

1) Max. rating factor P/n1= generator power/engine speed (kW/rpm). Higher rating factors on request

2) Other dimensions for centre distance H1 and hollow shaft dia. D1 on request

3) Dimensions D2, D3, D4 and L1 are valid for the appropriate size of coupling for the stated max. ratig factor.

4) Weights (dry) including mounted oil supply and monitoring system, but without VULKAN RATO-S coupling.